Our controllers are designed to control all types of API 612 Special Purpose turbines including single valve and multi-valve turbines, single extraction/admission turbines as well as double extraction/admission turbines. The CCC Speed and Extraction controllers provide high quality control accuracy and improved machinery protection through our advanced control algorithms. 3 Bell & Gossett SU steam-to-fluid heat exchangers are used primarily to heat a fluid in the tube bundle with steam. Designed to be flexible to meet your steam turbine control needs It also can lead to longer start times and machine trips during the start sequence.

STEAM CONTROLLER MANUAL MANUAL

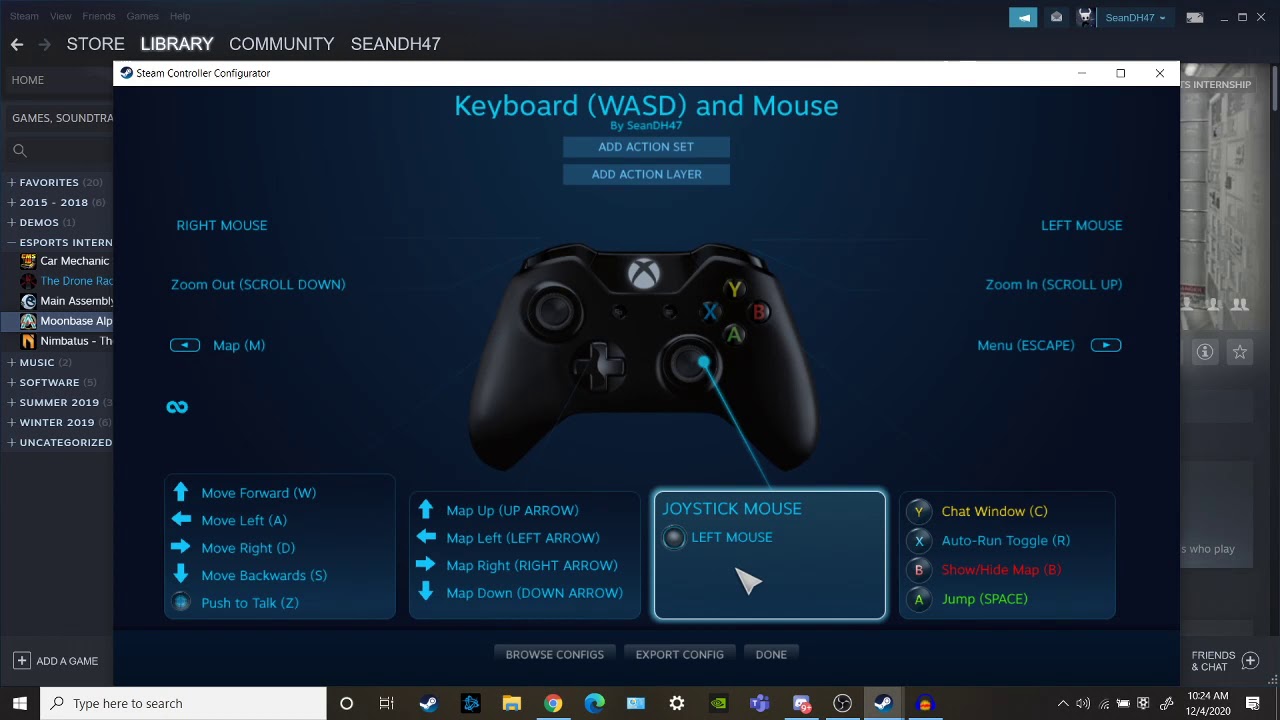

The Tower Controller (so called because he is the only. Manual control leads to inefficient operation as well as increasing the risk of machine and process trips. It also can lead to longer start times and machine trips during the start sequence. Global Air Traffic Control Aeoot GH 10 11 The Departure controller accepts the aircraft shortly after they leave the runway and guides them via SID procedures (Stand-ard Instrument Departures, see the chapter on procedures) to the Airway they will use enroute to the destination. Manual control leads to inefficient operation as well as increasing the risk of machine and process trips. Less than adequate speed control often results in manual control or frequent operator intervention in order to overcome speed fluctuations. You can do this by clicking the little controller symbol in the top right of the steam window. Start by plugging the dongle that came with the controller into an available USB socket, then fire up steam and launch into Big Picture Mode. Having high quality control for the steam turbine ensures the process remains stable with the highest possible efficiencies as well as increased reliability. The first thing you aught to do is setting up your steam controller.

Remembering Naum Staroselsky – Our Founder.Turbomachinery and Process Optimization Studies.Facebook Twitter LinkedIn Was this article helpful. Elite Control Product Manual (81037) Item Numbers: Kit with steamhead: EC-NTS-XX. The steam regulator should not be over-sized. To prop-erly size the regulator, the available inlet steam pressure and the heat exchanger design operating pressure must be known. The steam regulator should be sized based on the maximum lb./hr. See the product data manual for location of component parts terminal locations. Engineering Design Services During FEED Elite Control Product Manual Martin Siwy Updated Janu14:33. This will also provide the smallest size steam regulator. R7910A SOLA (HYDRONIC CONTROL) AND R7911 SOLA (STEAM CONTROL) SYSTEMS 66-117413 4 Checkout Summary Table 1 provides an overview of checkout steps performed for each applicable system.

0 kommentar(er)

0 kommentar(er)